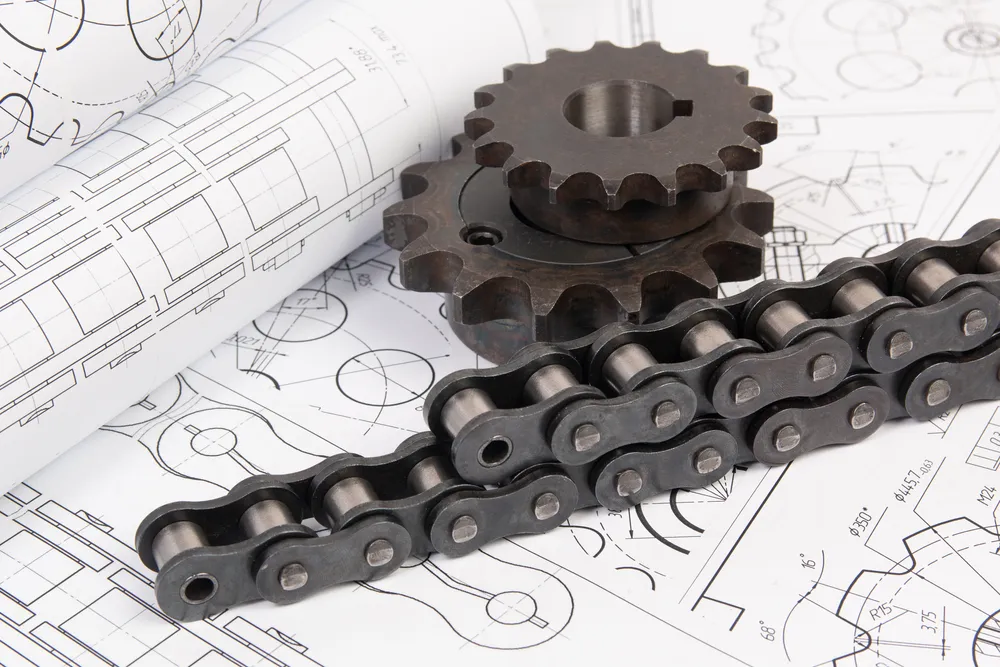

Hollow Pin Chain Manufacturer

We are a premier supplier offering a wide range of options including hollow pin roller chains. Our stock includes ANSI, ISO, DIN, Metric, Stainless Steel, Nickel Plated, Double Pitch, and conveyor series hollow pin roller chains. What distinguishes us is our variety of quality options and in-stock items, supported by knowledgeable customer service staff. Hollow pin roller chain finds applications in light to medium conveying, drive, bakery, circuit board manufacturing, elevating conveyors, and more. Additionally, we provide a comprehensive range of high-quality sprockets, belting, motors, gearboxes, bearings, sensors, and other products.

Hollow Pin Chain

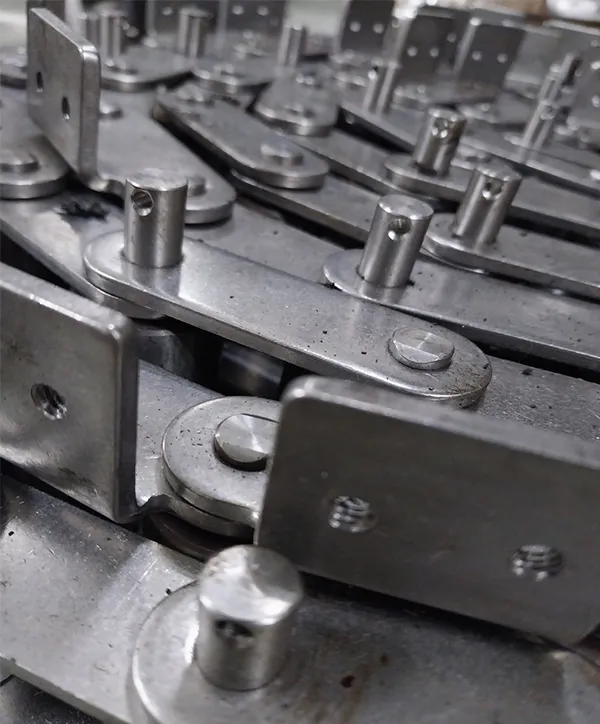

Hollow pin chain refers to a specific type of roller chain that features hollow pins instead of solid pins found in traditional roller chains. A roller chain is a type of mechanical transmission chain commonly used in various industrial applications to transmit power between two rotating shafts.

The hollow pins in a hollow pin chain are essentially cylindrical tubes with open ends. These pins are designed to engage with the chain sprockets and carry the load as the chain moves. The hollow pins provide several advantages over solid pins in certain applications:

Weight reduction

Hollow pin chains are typically lighter than standard roller chains due to the hollow construction of the pins. This weight reduction can be beneficial in applications where minimizing the overall weight of the chain is important, such as in conveyor systems or lightweight machinery.

Versatility

The hollow pins offer additional functionality by providing a space where other components or accessories can be inserted or attached. This allows for customization and flexibility in various applications. For example, attachments such as extended pins, extended plates, or specialized fittings can be inserted into the hollow pins to accommodate specific needs.

Lubrication Access

The hollow pins provide an access point for lubrication, allowing lubricant to be applied directly to the bearing surfaces inside the pins. This helps to reduce friction and wear, leading to improved chain performance and longevity.

Hollow Pin Chain for Sale

As a hollow pin chain manufacturer, we will do our best to serve you. If you need customized products, or the products you need are not found on our website, or need a product catalog, don’t worry, more of our products are still being uploaded. You can email us directly, and we will reply to you within 24 hours!

Precision Manufacturing Process

Our precision manufacturing process at EPT is characterized by attention to detail and advanced technologies. We begin with a collaborative design and engineering phase, where we develop chain designs tailored to specific requirements using advanced CAD software. The selection of high-quality materials is crucial, ensuring strength, durability, and resistance to wear and corrosion. Cutting and forming processes are executed with precision, followed by heat treatment to enhance mechanical properties. Our chains undergo precision machining for accurate dimensions and smooth finishes. Surface coatings, such as zinc plating or specialized options, are applied to improve corrosion resistance. Throughout the process, our quality control team conducts stringent inspections and tests to maintain exceptional standards. This commitment to precision manufacturing allows us to deliver hollow pin chains renowned for their reliability, durability, and superior performance in demanding industrial applications.

Hollow Pin Chain Sprockets

Hollow pin chain sprockets are specialized components used in chain drive systems. Unlike standard chain sprockets, these sprockets feature a unique design that incorporates hollow pins. The sprocket teeth are spaced evenly around the circumference, and the hollow pins are inserted through the center of each tooth. This design allows the chain to engage with the sprocket and transmit power effectively. Hollow pin chain sprockets are commonly used in applications where easy assembly and disassembly of the chain are required, such as conveyor systems or machinery that frequently requires maintenance or component replacement. The hollow pins provide accessibility for quick and convenient chain installation or removal without the need to disassemble the entire drive system. Additionally, hollow pin chain sprockets are known for their durability and resistance to wear, ensuring long-lasting performance in demanding environments.

Workers

industry experience

Customer Service

Advantages of Hollow Pin Chains

Lightweight Yet Strong

Hollow pin chains offer a lightweight design that eases handling and reduces strain on equipment. Despite their lightness, they possess excellent load-bearing capacity, making them suitable for heavy-duty applications.

Durable and Versatile

These chains exhibit resistance to corrosion and wear, ensuring a longer lifespan and reduced maintenance costs. They are also compatible with various attachments and accessories, allowing for customization and versatility in industrial applications.

Latest from the Blog

China high quality High Precision Convey Roller Chain Hollow Pin Roller Chain 08bhp Stainless Steel Roller Chain

China OEM Stainless Steel Cast Drive Roller Pintle Conveyor Industrial Duplex Drag Link Engineering Chain Leaf Hollow Pin Elevator Silent Hoisting Agricultural Escalator

China Good quality Conveyor Transmission Motorcycle Industrial Carbon Stee Roller Chain Short Pitch Precision Stainless Steel Hollow Pin

Hollow Pin Chain Application

Hollow pin chains find applications in various industries and systems where their unique features and advantages are beneficial. Here are some common applications of hollow pin chains:

Conveyor Systems

Hollow pin chains are widely used in conveyor systems for material handling, such as in manufacturing plants, warehouses, and distribution centers. They provide reliable power transmission, smooth operation, and the ability to accommodate attachments or fittings for specific conveying needs.

Packaging Machinery

Hollow pin chains are utilized in packaging machinery, including filling machines, labeling machines, and packaging lines. Their lightweight construction helps reduce the overall weight of the equipment, ensuring efficient operation and increased productivity.

Food Processing Equipment

The food industry often requires specialized chains that can be easily cleaned and maintained. Hollow pin chains, with their access points for lubrication and the ability to insert specialized fittings, are commonly employed in food processing equipment, ensuring hygienic operations and easy maintenance.

Material Handling Equipment

Hollow pin chains are used in various material handling equipment, such as bucket elevators, hoists, and lifting systems. The ability to customize the chains with attachments allows for secure attachment of buckets, hooks, or other load-carrying devices, facilitating efficient movement and transport of materials.

Automotive Industry

Hollow pin chains can also be found in automotive applications, particularly in engine timing systems. They are used to synchronize the rotation of camshafts and crankshafts, ensuring precise valve timing and efficient engine performance.

Agricultural Machinery

Hollow pin chains are employed in agricultural machinery for tasks like crop harvesting, hay baling, and grain conveying. Their versatility and adaptability make them suitable for diverse agricultural applications.